piACC-Mini-Min-V6

Forums:

V6

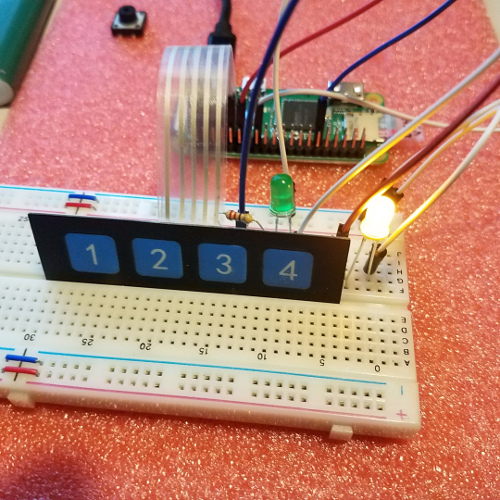

Mini-Min is now completed (sans 3d printed wrapper) This will probably end up being the unit that I use in my Jeep.

This will probably end up being the unit that I use in my Jeep.On my last venture to MicroCenters I was able to pick up a few of the "four button touch" pads.

Nicely, the ribbon cable plugs directly into the GPIO using the top row, last 5 pins.(Ground,GPIO,GPIO,GPIO,GPIO)

I had some serious difficulties getting it all to work code-wise though. Python code worked every time, however the service failed each time.

I put in a 1 second delay which it seems to like better, but yet another second added to boot/ready.

Being limited to only 4 buttons however caused another problem. Not enough buttons for reboot and shutdown of the unit.

I added code for a combo-button press which got me over that hurdle.

Buttons 1-4 control relays 1-4.. nice.

I also added an LED (yellow) to display "blue tooth connected" and another LED (green) to display "some light is on".

For combination buttons, if you press two buttons within 1 second (hopefully not accidentally) it will evaluate them as a command.

Command Buttons

1 & 3 = reboot the button controller.1 & 4 = shut down the button controller.

2 & 3 = Sends reboot command to the relay controller.

2 & 4 = Sends shut down to the relay controller.

This should keep the unit quite minimal in size.

The 4 button pad will be mounted length-wise with the pi zero, it is almost the exact length/width dimension-wise as the pi with the GPIO header.

Direct solder minus the header is an option but this way seems much easier and I would still need pins for the pad ribbon cable.

A backup of the micro SDC and this one is finished and ready for use.

- Log in to post comments